Ing. LA FALCE s.r.l.

Premium Partner

Ing. LA FALCE s.r.l.

Product / Services

NO-DIG TECHNOLOGIES

Different technologies for different projects

Chek the web page about no-dig services 👉 https://www.lafalce.it/en/tecnologie_eng/

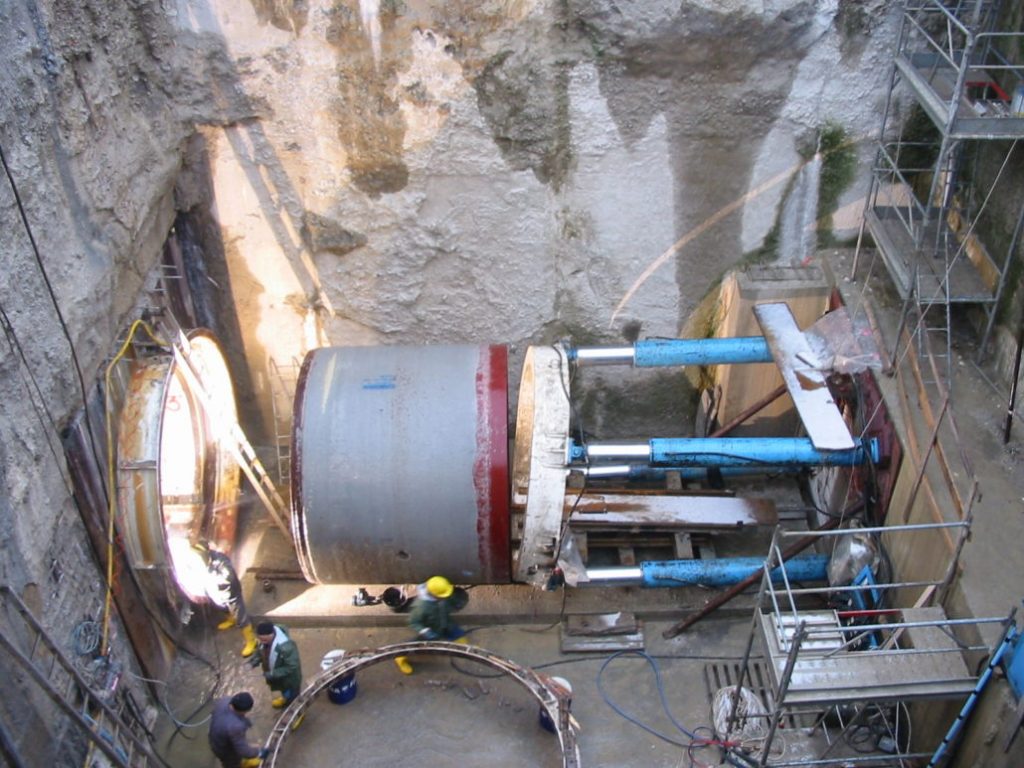

✅ MICROTUNNELLING

Microtunnelling is a drilling method that consists in a tunnel excavation machine without an operator on the excavation front, pipes are laid and push between two wells, with a remote control performed through a control unit located on the surface.

The system is composed of a milling head which breaks up the ground and which through its rotation movement directs it towards the mud line. The head is equipped with suitable digging tools, different according to the terrain to be tackled. The milling head is also equipped with a swivel joint which, through appropriate remote-operated hydraulic pistons, allows you to “guide” the head during drilling.

The second fundamental component of Microtunnelling consists of the thrust unit housed in the well (called thrust for this) which allows the insertion of the pipes into the tunnel dug by the milling head. The insertion of the pipes takes place thanks to the pressure exerted on them by the main pistons that find contrast on the wall of the thrust shaft which for this reason must be adequately sized. The thrust on the milling head is transferred from the pipes on which the force exerted by the thrust unit acts.

For microtunnelling, hydraulic slurry machines are used, equipped with a conical crusher, thanks to which the excavated material is crushed and conveyed into a chamber located behind the milling head (chasm chamber), from which it is pumped in the form of fluid (slurry) into the surface separation plant. More rarely mechanical slurry machines are used.

✅ OPEN SHIELD

The drilling machine in the “Open Directional Shield” technique consists of an articulated head, hinged on three or four hydraulic cylinders that allow it to be directed, and the main body that contains most of the excavation and collection equipment for the slurry as well as the control and pilot console. The main body can be equipped with autonomous push cylinders.

In the first case, the drilling takes place by excavating the ground by means of a bucket mounted on a hydraulic arm which conveys the material on a conveyor belt and therefore in mining wagons. In the second case, the stone ground is demolished by a point drill and subsequently removed by a hydraulic slurry system.

✅ AUGER BORING

The technique consists of laying pipes by pushing and simultaneously drilling the soil by means of a rotating drilling head. The excavation is open facing and the evacuation of the resulting material takes place by means of an auger that transports the material (smarino) from the excavation front to the outside.

The first phase involves the construction of the thrust chamber, of adequate size for the housing of the auger. Subsequently, the earth auger is placed in the planar altimetric operating position using the reference points set up during the tracing of the thrust direction.

The first tube to be inserted with the first auger inside is positioned on the frame of the auger, which has both the function of cutting edge (by means of a milling plate placed on the tip), and of removing the resulting material.

The pipes are driven in by welding the next pipe to the first pipe that has penetrated the ground, and so on. During the thrust, the thrust pressure, the rotation speed of the auger, the effective insertion length, the consistency and type of the excavated material are continuously monitored. At the end of the drilling the augers are recovered.

✅ SEGMENTATION TUNNEL

With this technology, unlike the pipe pusher, the tubular elements are not pushed from the starting well, but assembled inside the excavation machine (TBM or directional shield). The segments once assembled to form the ring constitute the contrast that allows the excavation machine (TBM or directional shield) to advance by pushing the hydraulic jacks with which the machine is equipped.

With this technology, tunnels of kilometric lengths can be created without the need for intermediate wells or intermediate stations for resuming thrust.

✅ THRUSTING OF BOX-LIKE PRODUCTS

In the case of pushing boxes under railway lines, to allow the insertion of the artefacts in the presence of railway traffic, (so-called “level rails”) the support of the rails occurs either by means of bundles of rails or by the so-called Essen bridge.

In the case of “underground” road / highway underpasses, the box end product is equipped with a metal rostrum and “anti-dragging” plates are positioned to reduce the friction between the ground and the product itself to obtain a reduction in the dragging phenomenon. in order to check the roadway subsidence.

Gallery